Reduce waste by choosing solar panels more responsibly

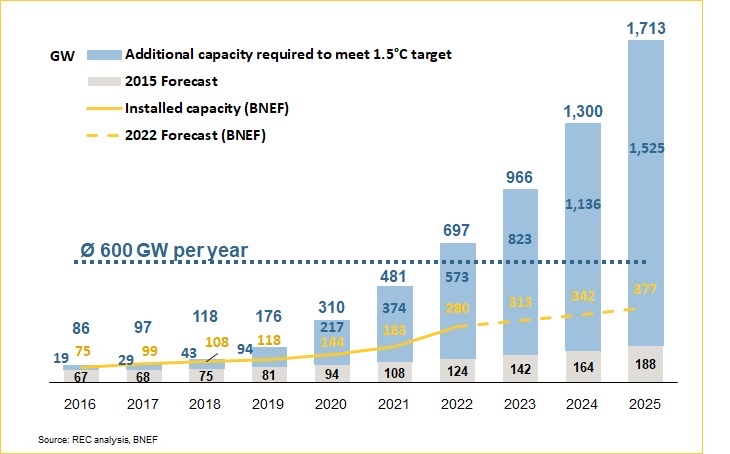

According to a study by REC Group, in order for solar energy to make a contribution towards limiting the global temperature increase to 1.5°C, we will need to install about 500 to 600 GW of new solar photovoltaic (PV) capacity on average per year. This is the equivalent of approximately 1.2 to 1.5 billion solar panels of 400 Wp power every year.

But as we race towards installing more solar panels to harvest energy, the solar industry needs to ensure that solar panels don’t morph from today’s solution to tomorrow’s problem. The industry needs to consider how it can deliver this through new product innovations that combine the development of higher efficiency solar panels with better long-lasting performance along with sustainable manufacturing practices.

Producing solar panels for the long-term

The International Renewable Energy Agency (IRENA) has predicted that large amounts of solar PV panels will end up in the waste stream by the early 2030s as the adoption of rooftop solar grows. So, at the heart of sustainable design is to create products that are built to last and high perform reliably through the entire product lifetime. The math is simple: By creating solar panels that last and perform for decades, the later they will need to be replaced and we will significantly reduce the amount of waste that we send to recycling or landfill.

In order to extend the lifespan of solar panels, we need to consider how solar panels should be designed to withstand more severe weather conditions. By introducing support bars at the back of panels for example, innovative manufacturers are ensuring that their panels can withstand heavy snow or wind loads of up to 7,000 Pascal.

Innovative design and technology combined with stringent testing guarantee that solar panels reliably maintain high energy yields throughout their lifetime and provide peace of mind for consumers. Solar panels by top manufacturers should have a 25-year product and performance warranty and guarantee at least 92% of nameplate power in year 25.

Producing panels that are fit for recycling

IRENA estimated that by 2050, there would potentially be 78 million tons of solar PV waste that could be recycled or repurposed. This poses a significant challenge as the complete recycling of solar PV panels has yet to be fully implemented globally. National regulations, such as the WEEE directive within Europe, as well as the adequate local infrastructure are needed across all growing solar markets worldwide.

Further research and innovation need to be carried on so that full recycling of solar panels can be ensured in a sustainable and cost-effective manner on a global scale. Materials such as glass, aluminum, plastics to copper can be recovered through a recycling process and returned for industrial production. But the recycling of the remaining crashed silicon laminates mix is still a challenge today. Without a change in design and production processes, the world would face a large solar PV waste problem.

The impact of toxic chemicals in manufacturing

The RoHS Directive ("Restriction of the Use of Certain Hazardous Substances in Electrical Equipment") limits the use of hazardous substances in all electrical and electronic equipment. However, solar PV panels are exempt from this environmental regulation, and this has allowed hazardous substances such as lead to be used in the production of solar panels across the industry.

Most solar panels contain a small amount of lead in relation to its total weight as this is used in soldering. Solar panels that use silicon wafers, which make up approximately 90% of the market, can contain around 24 grams of lead in a panel that weighs roughly 20 kg. To put this into perspective, around 400 million solar panels were produced worldwide in just one year. If we fast forward this into a few decades in the future, the production of solar panels in just one year will add around 10,000 tons of lead into the ecosystem.

The toxicity of lead to humans and animals has long been known. Lead released into the environment can make its way into the air, soils, ground water and also food. How a solar panel is treated at the end of its life determines the environmental impact it may cause when it is disposed. The disposal of a solar panel that contains lead can cause lead leakage into the ecosystem, putting our food chain in danger.

Leading a future without lead

Since 2012, REC has been pushing for a lead-free future in the solar industry by setting the pace for more sustainable solar. In 2019, REC introduced lead-free solar cells in its first HJT Alpha technology. In 2021, we launched the REC Alpha Pure solar panel, where we removed lead from all other soldered components, so cross-connectors, junction box and connectors. To achieve this, REC sourced lead-free components and then worked to find the best mix and temperatures to provide as good a performance as the baseline. REC’s Alpha Pure solar panels have been independently tested by a third-party to confirm that it is lead-free and is RoHS-compliant. The reports show that there is no trace of any of the 10 substances above the detection level of the test machinery used.

“From a pure manufacturing and cost perspective, lead in soldering is making the production easier,” explains Shankar G. Sridhara, Chief Technology Officer at REC Group. “However, considering the impact to the society and environment, it should bother us all. Getting rid of lead in solar panels is worth to go the extra mile and simplifies also the recycling of solar panels at their end of life.”

This is why REC believes it is important to consider solar panels that are designed with the environment in mind during the product development lifecycle. Eliminating lead and other hazardous materials makes the recycling of solar panels far easier at the end of a solar panel's life. However, the best way forward isn’t about creating a product that needs to be recycled but rather focusing on designing a product that has a longer lifespan, performs efficiently and reduces the use of resources when its manufactured. Homeowners who want to play their part in mitigating climate change can choose responsibly made solar panels that will boost their positive impact and lower their environmental footprint.

See how REC is contributing today for a better tomorrow: CSR by REC

Learn more about REC’s award-winning Alpha Pure Series: REC Alpha Pure